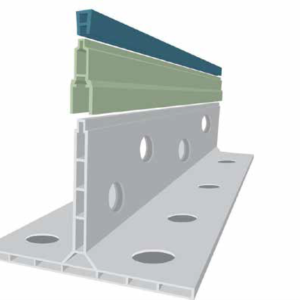

K-Form is made from uPVC. In simple terms it’s a lightweight cast in-place permanent screed rail that’s strong enough to handle all types of conventional mechanical screeds.

It’s fast and easy to put in place. Plus it provides control, construction and isolation joints. In other words, you set up, pour and the K-Form simply stays in the ground.

- Comes in 2.8m Lengths for ease of handling.

- Ultimate construction joint for external hard stands, driveways, residential slabs and warehouse applications where steel joints are not needed.

- Speed up your construction – no delays stripping formwork from ‘Hit and Miss’ pours

- Non – Corrosive so ideal for those application where chemical or salt corrosion is an issue

How it works

Australasia’s premier Construction Joint System

Placing concrete has traditionally involved setting up a series of wooden boxes and then concrete is poured into alternate sections.

After the concrete has dried, the boxing is dismantled and a new load of concrete goes into the sections missed the first time around – hence the name ‘hit and miss’ pouring.

While this method of pouring concrete is well-established and fairly straightforward, the process has always had drawbacks. A major issue is the amount of time it takes – because you’re being forced to sit through the drying process before you can pour again. Cutting control joints into the concrete with a diamond saw adds more time on top this

key benefits

- 2.8m Lengths – ease of handling

- Manufactured from lightweight, durable PVC

- Integral expansion joint and void cap

- Removable void cap/screed rail

- Pre-drilled holes for dowel placement

- Plate dowel option

- Ideal for setting heights where there are multiple falls.

- One person can install

- Can be used with most screed methods

- Non-conductive

- Reduces the need for saw cuts

- No cleaning or removal, unlike traditional forming methods

- Fuel, oil, and chemical resistant

- Never rots or rusts

specifications

ALL THE DETAILS YOU NEED.

PRODUCT INFORMATION

AND DESIGN SPECIFICATIONS

Downloadable product information, technical data sheets, MSDS and architectural specifications.

Product Range

-

$127.91 – $203.86

$127.91 – $203.86Large Shim Pack 150x100mm (one size)

Casta’s large shims are designed for levelling and packing objects with a high load mass – often used to pack up precast/tilt panels in the industrial, commercial and civil construction industries.

The shims feature a gripped non-skid surface at a handy 150x 100mm.

-

$65.50 – $70.50

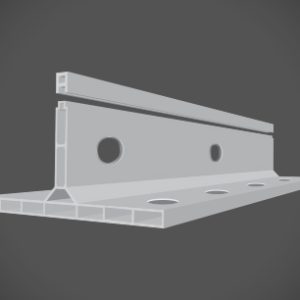

$65.50 – $70.50K85 x 2.8m

Designed for pours of 50 – 100mm concrete slabs.

The profile is made of durable PVC, with a built-in expansion joint. Once concrete is poured, K-FORM is left in place; no need to remove and clean. Separate Void Cap can be removed once concrete is set to allow joint sealing.

*Price includes a 2.8m K85, top strip and 1 x joiners per length.

-

$78.34 – $83.34

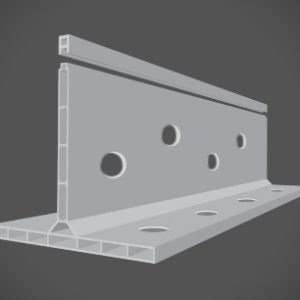

$78.34 – $83.34K135 x 2.8m

Recommended for forming 150 – 225mm concrete slabs.

Once concrete is poured, K-FORM is left in place; no need to remove and clean. Separate void cap can be removed once concrete is set to allow joint sealing.

*Price includes 2.8m K135 length, a top strip and 2 x joiners per length of K135.

-

$18.90

$18.9025mm Riser

K-Form 25mm risers are used to increase the height of the K-Form construction joints for larger slab pour depths. Simply clipping onto the top of K-85 and K-135 they are very easy to setup while remaining sturdy for larger pours.

-

$1.91

$1.91Hold Down Pin

K-Form Hold Down Pins are ideal for pinning the K-Form construction joint to the sub-base making setup up easy. With a sharp point the simply pierce the K-Form and hold it firmly in place for the concrete pour.